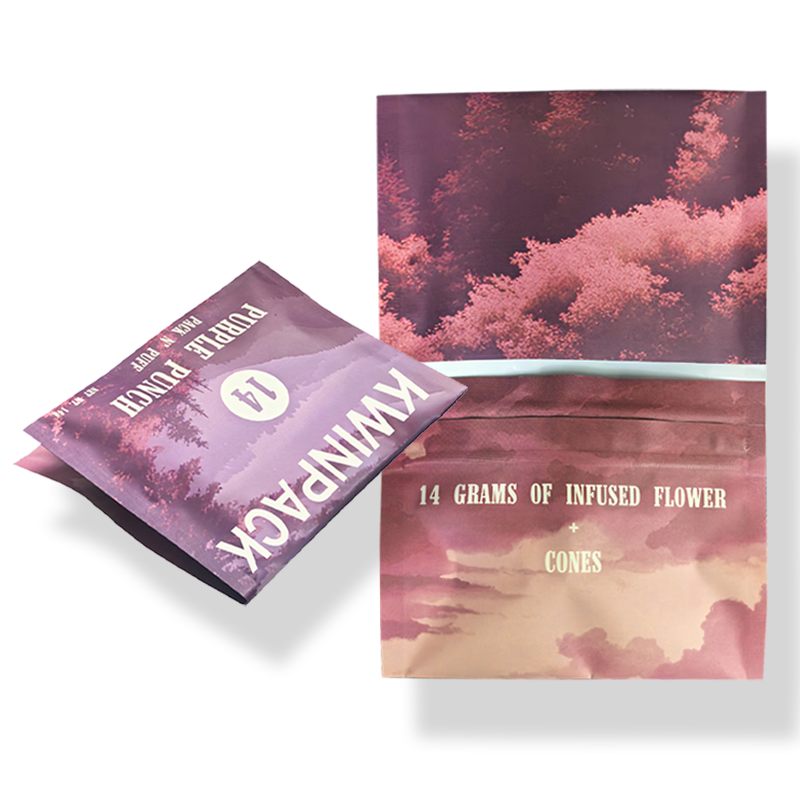

From ready meal lidding films to vacuum skin packaging our products are designed to protect, present and preserve food in a way that reduces waste and enhances the consumer experience. All our pouches and bags are produced with the highest technical integrity within Europe, under BRC and ISO 9001:2015 guidelines.

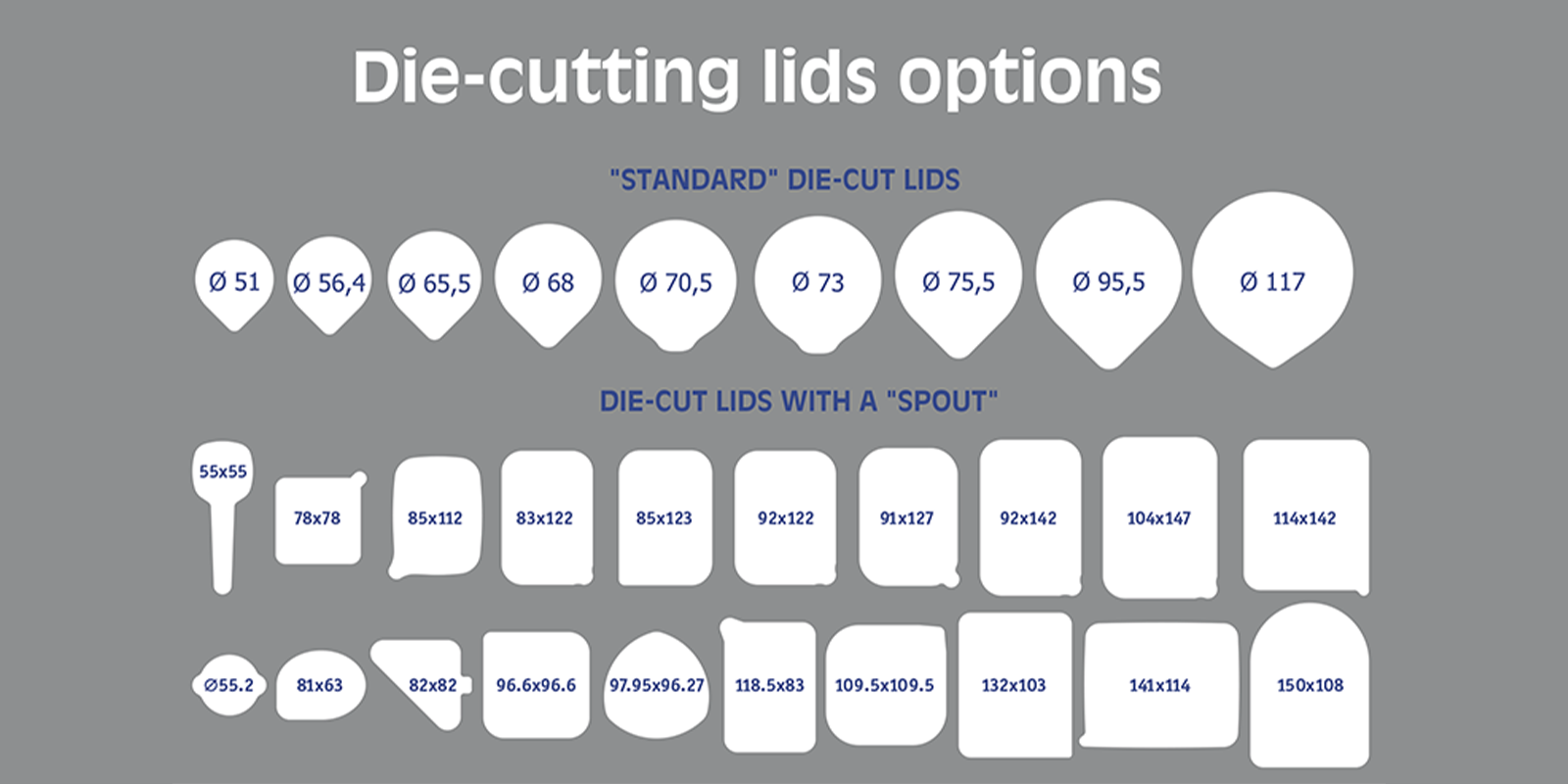

Depending on your needs, we can offer a range of lidding films that allow for different sealing methods. From extra secure seals for high-value products to resealing functionality to help preserve freshness, our lidding films can do the job you need.

We supply lidding films suitable for use in the microwave, as well as ovenable packaging so food can go from factory to table without having to be opened until ready to eat, the ultimate in consumer convenience and safety.

We also offer easy-peel features for greater consumer convenience and perforation options to improve food preservation without the risk of contamination. Our lidding films can also be produced with additional laminate layers to help fulfil further protective requirements.

Characteristics

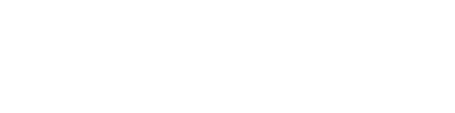

Suitable for sealing on various materials such as PP/PS/PET/PE etc, Top sealing of jointed tube packaging once well saves time and labour, The sealing is film but easy to tear with good airproof and fresh-retaining properties. The rollstocks have nice heat sealability thus will not delaminate after the pasteurization process.

Different lamination solutions for different purposes. High performance with different materials lamination.

Choosing the right cup sealer film is crucial for maintaining the freshness and integrity of your products. Whether you own a cafe, restaurant, or food delivery service, having the right film can make a significant difference in preserving the quality of your beverages.

Conclusion and final tips for choosing the perfect cup sealer film

Choosing the perfect cup sealer film for your business is crucial for maintaining the freshness and quality of your beverages. Consider factors such as compatibility with your cup sealer machine, material thickness, sealing durability, and food safety compliance. Additionally, prioritize cost-effectiveness and sustainability by selecting films that offer a balance between price and performance.

By understanding the different types of cup sealer films, their features, and the factors to consider, you can make an informed decision that meets your specific needs. Remember, the right cup sealer film can make a significant difference in preserving the integrity of your products and enhancing your customers’ satisfaction. So, choose wisely and seal your success!