Custom Snack Bags Packaging

Snack packaging bags are essential for protecting, preserving, and presenting a wide variety of food products. Made from advanced multi-layer films, these bags provide excellent barrier properties against oxygen, moisture, and light, significantly extending product shelf life. Available in various styles including stand-up pouches, vacuum bags, and shaped designs, they offer both functional advantages and powerful marketing appeal. With features like resealable zippers and easy-tear openings, modern snack packaging ensures product freshness while enhancing consumer convenience and brand visibility in competitive markets.

- Overview

- Recommended Products

| Product | Custom Mylar Snack Food Packaging Plastic Bag with Zipper Milk Tea Powder Bag Stand Up Pouch Deep Freeze Powder Pouch Bag |

| MOQ | 500pcs. More quantity, more favorable price. |

| Material | PET/VMPET/PE or customized. |

| Thickness | 40-200microns. |

| Printing | Customized. Up to 9 colors. CMYK/Pantone |

| Packing | First in clear OPP bags, then in standard export carton. Pallet request is acceptable. |

| Feature | Food Grade, High Barrier, Moisture Proof, Strong Sealing, Perfect Printing |

| Quality Control | Advanced Equipment and Experienced QC Team will check material,semi-finished and finished products strictly in every step before shipping. |

Product Details Description

The Ultimate Guide to Snack Packaging Bags: Types, Advantages, and How to Choose

In the dynamic world of snack foods, packaging plays a pivotal role far beyond simply containing the product. It serves as a critical barrier against contaminants, a tool for extending shelf life, and a powerful medium for brand marketing. This article explores the various types of snack packaging bags, their unique advantages, and how to select the right bag for different snack products.

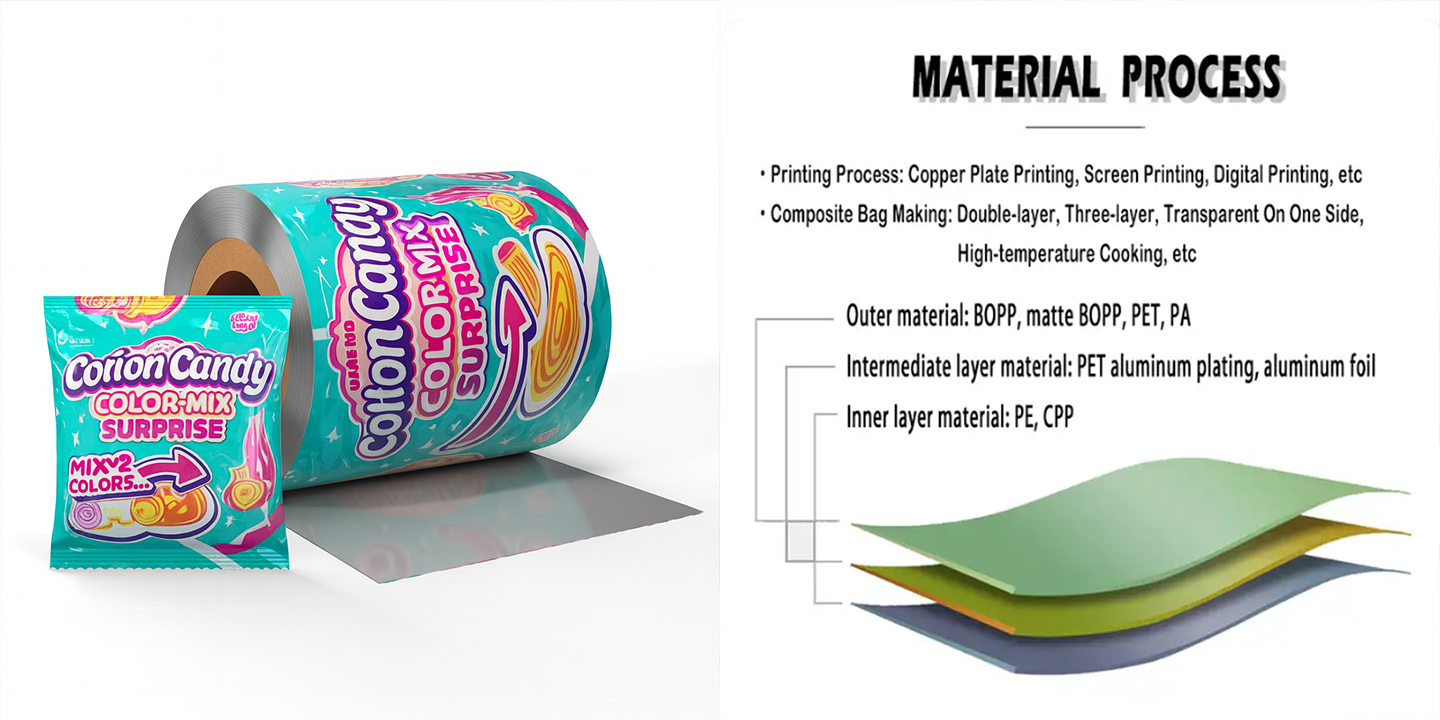

Plastic remains the material of choice for most snack packaging bags due to its exceptional versatility, durability, and protective qualities. Modern snack bags are often not simple single-layer plastics but sophisticated multi-layer composite films that combine the benefits of different materials. These layers typically include:

An outer layer of BOPP (Biaxially Oriented Polypropylene) or PET (Polyethylene Terephthalate) for excellent printability and mechanical strength to withstand transportation wear.

A middle functional layer for barrier protection, which may include aluminum foil (6-9 microns thick) to completely block light and oxygen, or metalized VMPET for selective barrier properties.

An inner sealing layer usually made of LLDPE (Linear Low-Density Polyethylene) or CPP (Cast Polypropylene), which provides a strong seal and is safe for direct food contact.

This sophisticated material engineering creates an optimal environment for preserving snack quality.

Types of Snack Packaging Bags and Their Advantages

1. Stand-Up Pouch

Advantages: Stand-up pouches feature a gusseted bottom that allows them to remain upright on shelves without support. This offers superior shelf presence and visibility compared to flat pouches. They often come with resealable zippers, which greatly enhance convenience for consumers by maintaining product freshness after opening. They are ideal for liquids, powders, and snacks consumed multiple times.

Ideal For: Potato chips, nuts, trail mix, powdered drinks, and liquid snacks like yogurt pouches.

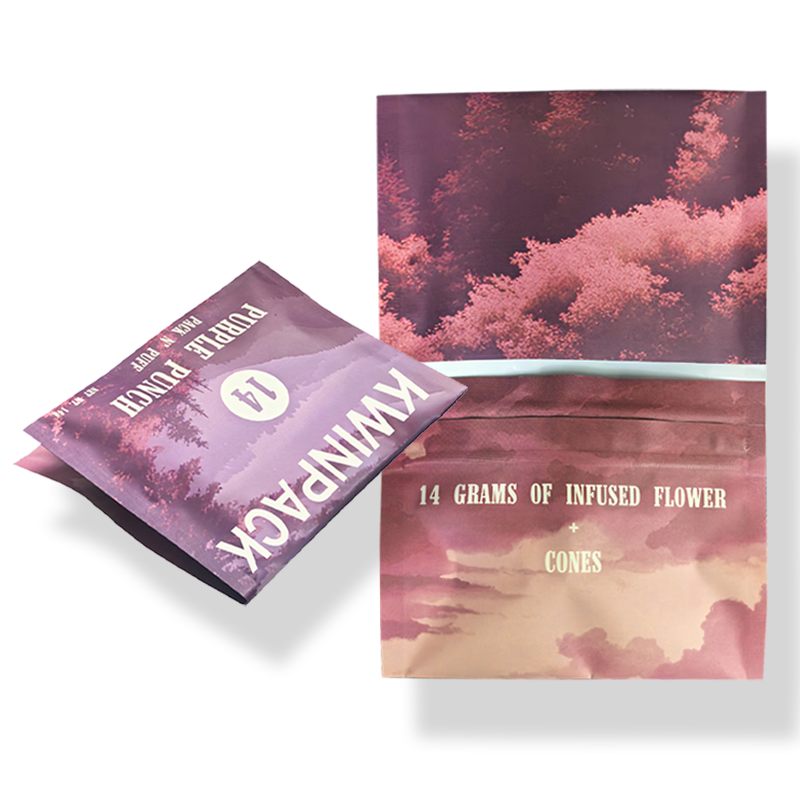

2. Three-Seal Side Bag

Advantages: This is a common and cost-effective option where the bag is sealed on three sides. It's simple to manufacture and offers a large, flat surface area ideal for high-impact graphics and branding.

Ideal For: Hard snacks like cookies, biscuits, candy bars, and single-serve dry snacks.

3. Four-Seal Side Bag

Advantages: Sealed on all four sides, this bag type offers enhanced seal strength and better stand-up stability than three-side seal bags. Its boxy structure provides better protection for the contents against crushing.

ozen snacks, products that require upright display, and fragile snacks that need extra protection.

4. Eight-Seal Side Bag

Advantages: A more advanced version that offers even greater structural integrity and a unique, modern appearance on shelves. The additional seals create a more three-dimensional shape, enhancing visual appeal and providing superior protection against crushing and impact.

Ideal For: Premium biscuits, cookies, and high-end snacks where distinguishing the product on the shelf and maximizing protection are crucial.

5. Shaped Bag(Die Cut Bags)

Advantages: These bags break away from traditional rectangular shapes using die-cutting technology to create unique forms (e.g., animals, fruits). They are highly effective at capturing consumer attention and can increase purchase conversion rates by up to 40% for targeted demographics like children.

Ideal For: Children's snacks, novelty candies, and premium products where standout packaging is a key marketing tool.

6. Vacuum Bag

Advantages: These bags have the air removed before sealing, creating an oxygen-free environment. This significantly extends shelf life (by 3-5 times) by preventing oxidation and inhibiting the growth of aerobic bacteria1.

Ideal For: Meat snacks, jerky, cheese, dried fruits, and nuts—any snack prone to oxidation and rancidity.

7. Pneumatic (Inflated) Bag

Advantages: Instead of removing air, these bags are filled with an inert gas like nitrogen. This cushions the contents to prevent crushing during transit and also displaces oxygen, helping to preserve freshness and prevent staleness.

Ideal For: Light, fragile snacks like potato chips, extruded snacks, and cheese puffs.

Selecting the optimal packaging depends on several factors:

Product Characteristics: Consider fat/oil content, moisture sensitivity, and fragility. Oily nuts need high-barrier materials like aluminum foil or metallized film, while dry snacks may do well with simpler materials1.

Shelf Life Requirements: Determine the required shelf life (e.g., 3 months vs. 12 months). Longer shelf life necessitates higher barrier properties, possibly with vacuum or gas flushing1.

Target Market and Consumer Preferences: Children are attracted to shaped bags, while on-the-go adults appreciate stand-up, resealable pouches for convenience.

Budget and Sustainability Goals: While standard plastic bags are cost-effective, there is a growing trend towards using biodegradable materials like PLA (polylactic acid) and PBAT, which can achieve a 90% degradation rate within 180 days under industrial composting conditions.

Conclusion

The humble snack packaging bag is a masterpiece of functional design and material science. It seamlessly blends product protection, marketing appeal, and user convenience into a single, cost-effective solution. From the common three-side seal bag to the innovative eight-side seal bag and the eye-catching shaped bag, each type offers distinct advantages tailored to specific snack products and market needs. As technology advances, the future of snack packaging lies in smarter, more sustainable materials and designs that continue to push the boundaries of freshness preservation and consumer engagement while reducing environmental impact. Understanding these options is key for any brand looking to succeed in the competitive snack food industry.